Our tools for your success

Let us present to you an excerpt of our instruments for the development of your individual product. Not just our experience did grow over the years, but also the spectrum of possibilities to work for you more efficient, economical and transparent:

Development of a Model

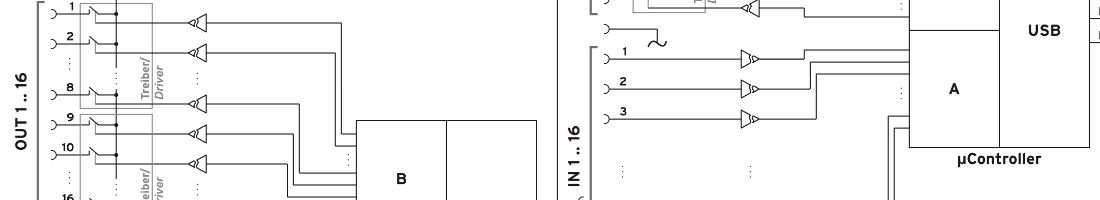

Block Diagram

On the basis of the initial communication with the client and after all requests and ideas have been acquired, we can create the first block diagram. It displays a rough set up of the product and its most important hardware components.

3D Model

Now we implement the first 3D model of the product on basis of the block diagram. This helps the client to visualize his project.

Download: Example of a 3D model

(The latest version of Adobe Acrobat Reader is required to display the 3D-PDF file)

Development of a Prototype

Circuit Diagram – Altium

The next step is to develop a circuit diagram. It contains all components and the connections of the planned products. In this stage initial thoughts regarding the software and firmware will come up, too.

Component Management – E-Tool

Our in-house software "E-Tool" connected up with the high end software by "Altium" makes it possible to set up an optimized and extremely economical supply chain at this very early stage of the development.

The advantage for the client is the consistent quality and availability of components in the series over a prolonged period of time. As well as a very good value for money thanks to the profitability of the development in this way.

Placement & Rooting – Altium

In this stage the board (PCB) of the product is designed. After settling the mechanically relevant parts, the components are placed on the board. Then the conducting paths are installed in the process of rooting. After finishing the board, it will be checked according to predefined rules. These rules contain electrical and production-orientated aspects. Only if the results of this test are 100% positive, the CAM data is created and electronically passed on to the manufacturer of the PCBs.

Prototyp

Whilst the boards are in production, the component purchase is taking place. As soon as all parts are added to the stock, the sample is picked and placed by us.

The precise digital execution makes sure that the first prototype looks extremely similar to the digital version. As soon as the prototype is there, the software can be developed.

Software

Firmware

We also provide a range of various tools for the firmware of measurement:

- IDE

- Compiler

- Debugger

- and many more

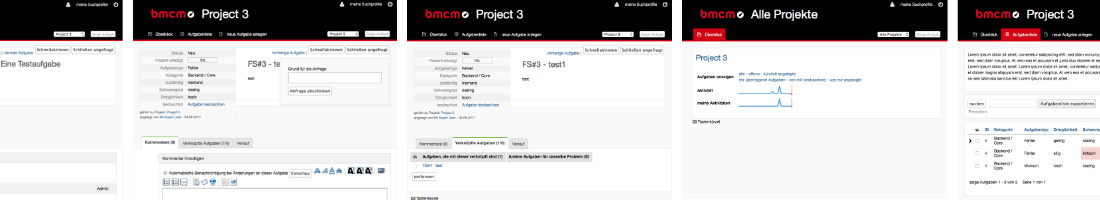

Flyspray

Now the client has to test the prototype for its functionality and application. The communication in this process takes place on our professional platform:

Flyspray

This is an easy to use web interface for collecting demands, wishes and faults. Every project owns an individually configured interface, matching all requirements. This way all changes and developments are documented in a transparent way for both sides. All alterations and the state of development are clearly visible at all times for everyone.

Development Pilot Run

EMV Tests

Thanks to cost intense investments in testing equipment we are able to test extraneous radiation and interference immunity in-house to accompany the development. This certainly does not replace examinations in accredited labs, which we can also conduct aside the development, if a CE compliance or similar is desired.

Thermo Tests

Thermo tests for the inspection of the temperature development of critical components can be performed in-house with our professional infrared camera.

Development of the Serial Product

Automated Test System

After the approval of the prototype the pilot run will be produced in preparation of the serial production. In this step the automated test system is created, too.